Stop Module with damping

No items found

ASM-500

For stopping and separating of one or more accumulated workpiece carriers on a defined workpiece carrier stop surface.

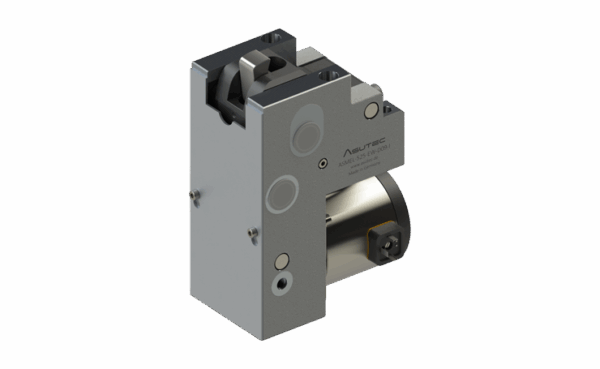

ASM-220

For stopping and separating of one or more accumulated workpiece carriers on a defined workpiece carrier stop surface.

ASM-15

For stopping and separating of one or more accumulated workpiece carriers a defined workpiece carrier stop surface.

Made for small transfer systems like Bosch Rexroth TS1.

Made for small transfer systems like Bosch Rexroth TS1.

ASM-600

For stopping and separating of one or more accumulated workpiece carriers on a defined workpiece carrier stop surface.

ASM-325

For stopping and separating of one or more accumulated workpiece carriers on a defined workpiece carrier stop surface.

ASMNG-15

For stopping and separating of one or more accumulated workpiece carriers a defined workpiece carrier stop surface.

Housing parts made of high strength, fiber reinforced polymer.

30% cheaper than the stop module ASM-15.

Made for small transfer systems like Bosch Rexroth TS1.

Housing parts made of high strength, fiber reinforced polymer.

30% cheaper than the stop module ASM-15.

Made for small transfer systems like Bosch Rexroth TS1.

ASM-1200

For stopping and separating of one or more accumulated workpiece carriers on a defined workpiece carrier stop surface.

ASM-360

For stopping and separating of one or more accumulated workpiece carriers on a defined workpiece carrier stop surface.

ASMS-20

For stopping and separating of one or more accumulated workpiece carriers on a defined workpiece carrier stop surface.

ASM-3000

For stopping and separating of one or more accumulated workpiece carriers on a defined workpiece carrier stop surface.

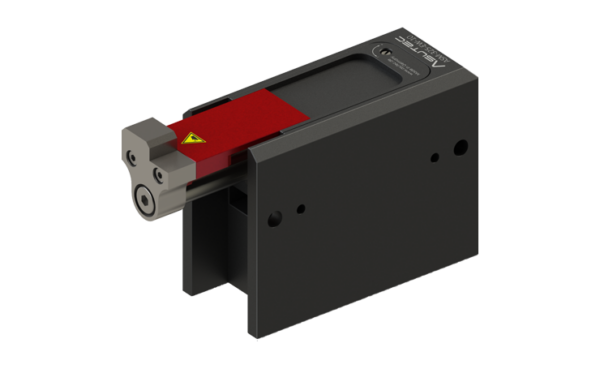

ASMEL-525

For stopping and separating of one or more accumulated workpiece carriers on a defined workpiece carrier stop surface.

The stoppers of the ASMEL-205/-525/-1050/-1850 series differ from the stoppers of the ASMEL-200/-500/-680/-1000 series in that the stop performs a pivoting movement when damping and that the damping unit can be screwed out. So the damping effect can be adjusted. This means that lighter workpiece carriers can be damped and stopped with less propulsive force. The damping end position is reached more reliable.

The ASMEL-525 features an exceptionally compact damping unit, allowing for easy installation even in confined spaces.

The stoppers of the ASMEL-205/-525/-1050/-1850 series differ from the stoppers of the ASMEL-200/-500/-680/-1000 series in that the stop performs a pivoting movement when damping and that the damping unit can be screwed out. So the damping effect can be adjusted. This means that lighter workpiece carriers can be damped and stopped with less propulsive force. The damping end position is reached more reliable.

The ASMEL-525 features an exceptionally compact damping unit, allowing for easy installation even in confined spaces.

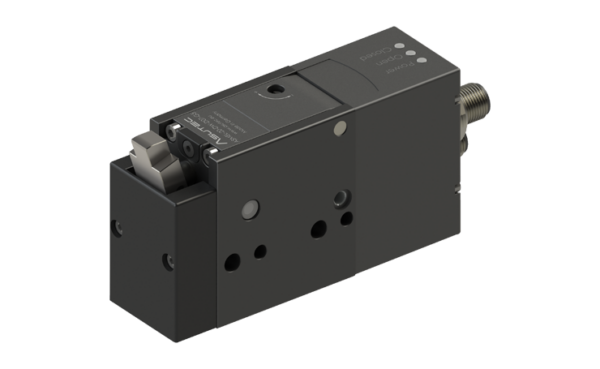

ASMEL-20

For stopping and separating of one or more accumulated workpiece carriers a defined workpiece carrier stop surface.

Made for small transfer systems like Bosch Rexroth TS1.

Made for small transfer systems like Bosch Rexroth TS1.