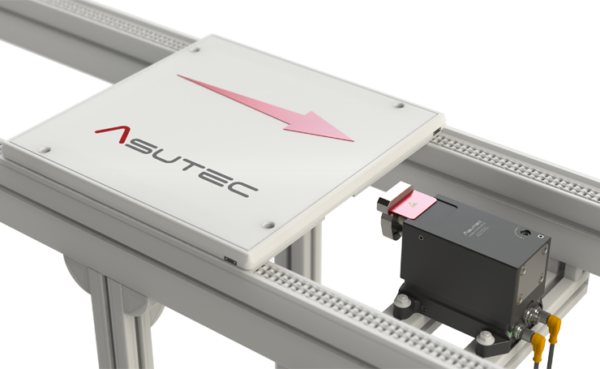

Stop module with damping ASMEL-610

For stopping and separating of one or more accumulated workpiece carriers on a defined workpiece carrier stop surface.

Technical data

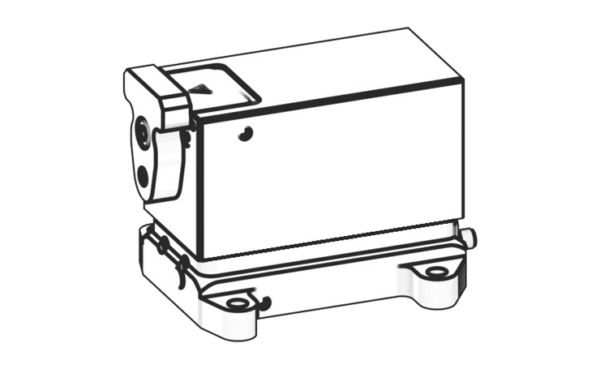

EXECUTION AND WEIGHT

EXECUTION AND WEIGHT

Device design: Basic housing made of hard anodized aluminum and stop plate made of hardened steel. Air damping system, adjustable damping effect

Weights of the devices:

ASMEL-610-DW-09-G5: 4,25 kg

CYCLE TIMES

CYCLE TIMES

Time to lower the stopper: 1 seconds

Time to rise up the stopper: 0,3 seconds

Minimum cycle time: 5 seconds

FUNCTION

FUNCTION

The electrical separator ASMEL-410 is a separators with damping. The damping is with air and can be finely adjusted via a throttle screw.

Further information are provided in the operating manual.

ELECTRICAL CONNECTION

ELECTRICAL CONNECTION

For normal operation, the separator is connected to the actuator connection (X1 Act) and to the sensor connection (X2 Sens). Both connectors have a size M12x1 and have 5-pins.

Further information are provided in the operating manual.

POWER SUPPLY

POWER SUPPLY

24 Volt ± 15%, with reverse polarity protection. If the voltage is higher or lower, the Power LED starts flashing in 0.25 second intervals. No more commands are executed. If the voltage range is between 20V and 28V again, then the Power LED is permanently on. The separator is then ready for use again.

POWER CONSUMPTION

POWER CONSUMPTION

Residual current: 0.1 A

Rated current 2,0 A

The current consumption of the separator takes place via the supply voltage of the actuator-connection (pin 4).

INPUT

INPUT

High-Pegel > 19 V

Low-Pegel < 8 V

OUTPUTS

OUTPUTS

High-Level = supply voltage – 1,2 V ( approx. 20 V … 27 V)

Low-Level < 1 V

LEDS

LEDS

The LED „PW’ (power) lights up green in normal operation

OPEN: The LED “NO” (opened) lights up yellow when the stop module is open (lowered).

CLOSED: The LED “NC” (closed) lights up yellow when the stop module is closed (in upper position).

TEMPERATURE RANGE

TEMPERATURE RANGE

+ 5°C up to + 60°C (without accessories)